A.C.S.C.

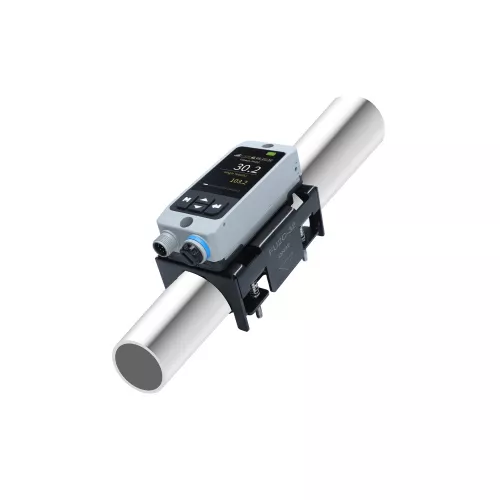

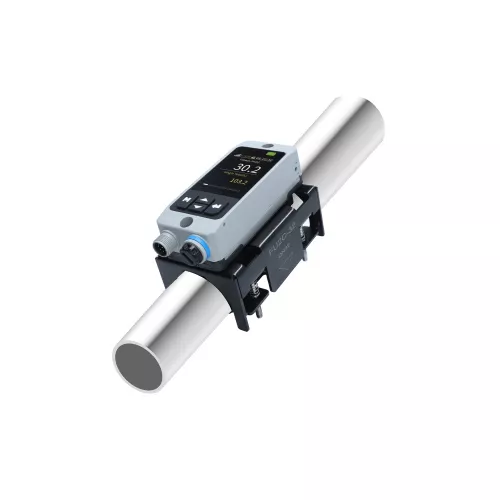

FUM03 Clamp-On Ultrasonic Flow Meter

FUM03 Clamp-On Ultrasonic Flow Meter

Price on Request

Important: This product is built to order and not available for direct online purchase.

Lead times may vary depending on supplier inventory. In some cases, components may need to be sourced from overseas before being assembled in Taiwan and imported to Australia.

As an Australian business, we handle the entire import process—no foreign currency, no customs forms. Just local delivery and reliable service.

Non-Invasive Liquid Flow Monitoring for Industrial, Water, and HVAC Systems

The FUM03 Clamp-On Ultrasonic Flow Meter offers high-accuracy, non-intrusive liquid flow measurement across a wide range of pipe sizes from DN8 to DN40, without cutting pipes or interrupting system flow. Ideal for use in HVAC cooling towers, wastewater treatment, energy monitoring, and process control, the FUM03 delivers ±1–2% accuracy, fast setup, and versatile outputs including analog, RS-485, relay, and pulse.

Engineered for industrial environments, the FUM03 installs in minutes with zero pressure loss or fluid contact—making it a reliable solution for corrosive, dirty, or mission-critical systems.

Key Features

- Clamp-on design – No pipe cutting or downtime required

- Pipe size compatibility: DN8 to DN40

- Output options: 4–20 mA, 0–10 V, RS-485 Modbus, Relay, Pulse

- Accuracy: ±1% to ±2% of full scale

- Display: 2.0" TFT screen with real-time flow and totalized volume

- Fast response time: Down to 0.5 seconds

- Fluid compatibility: Water, solutions, chemical reagents (≤4% impurities)

- User-selectable units: L/min, m³/h, configurable pulse unit

- IP65/IP67 protection | CE Certified | Compact enclosure

- No pressure loss | Non-contact ultrasonic sensing | Corrosion-resistant

- Supports flow direction, no-flow detection, and error alerts

Applications

- HVAC cooling tower water flow monitoring

- Water treatment and drainage detection

- Machine tool coolant system control

- Energy management and water consumption tracking

- Beverage and bottling lines (non-invasive CIP monitoring)

- Industrial process piping with limited access

- Leak detection and flow presence monitoring

Highlights for Feature Cards

- Clamp-on sensor for DN8–DN40 pipes

- Instant, analog, Modbus, and relay outputs

- Non-contact, no corrosion or contamination risk

- Works with stainless, copper, PVC, and PPR pipes

- Fast setup via pipe diameter input

- IP67 rated (select models) for harsh environments

Available Variants

|

Model |

Pipe Size |

Flow Range |

Output |

Power Supply |

IP Rating |

|

FUM03-08 |

DN8 |

0.6 – 19.6 L/min |

4–20 mA / 0–10 V / Pulse / Relay / RS-485 |

DC 24 V ±10% |

IP65/IP67 |

|

FUM03-10 |

DN10 |

0.94 – 30.62 L/min |

4–20 mA / 0–10 V / Pulse / Relay / RS-485 |

DC 24 V ±10% |

IP65/IP67 |

|

FUM03-15 |

DN15 |

1.06 – 53.0 L/min |

4–20 mA / 0–10 V / Pulse / Relay / RS-485 |

DC 24 V ±10% |

IP65/IP67 |

|

FUM03-20 |

DN20 |

1.88 – 94.2 L/min |

4–20 mA / 0–10 V / Pulse / Relay / RS-485 |

DC 24 V ±10% |

IP65/IP67 |

|

FUM03-25 |

DN25 |

2.94 – 147.2 L/min |

4–20 mA / 0–10 V / Pulse / Relay / RS-485 |

DC 24 V ±10% |

IP65/IP67 |

|

FUM03-32 |

DN32 |

4.82 – 241.15 L/min |

4–20 mA / 0–10 V / Pulse / Relay / RS-485 |

DC 24 V ±10% |

IP65/IP67 |

|

FUM03-40 |

DN40 |

7.54 – 376.8 L/min |

4–20 mA / 0–10 V / Pulse / Relay / RS-485 |

DC 24 V ±10% |

IP65/IP67 |

Note: This product is built to order and not available for direct online purchase.

Please refer to the Datasheet below for detailed specifications and available configurations.

Once reviewed, click “Enquire Now” to contact us. We’ll help match the right model to your installation type, output requirements, and display preferences.

Downloads: